CI3D Lab

About us

Color Imaging 3D (CI3D) Lab dedicates on developing the methodology of high quality color and 3D images. CI3D lab is a part of Graduate Institute of Color and Illumination Technology (CIT) in National Taiwan University of Science and Technology (NTUST), hosted by Dr. Tzunghan Lin. Established at 2011, CI3D severed many social responsibilities and has developed stereoscopy, various 3D scanning, augmented reality (AR) projecting, 3D printing et. al, technologies. Research interest includes computer graphics, computer vision, color science and human factor. CI3D focused on software algorithm, hardware framework and integration total solution. CI3D already owns several inventions, as well as patents, technological transfers, as well as products and international collaborations. For more details, please go to link.

Core value

Research position of our Lab

From the beginning of “photography”, we mainly dedicate on solving and processing “3D” relevant issues. Based on digital cameras, we focus on the framework, pipeline, on-site processing, post-processing, data generation for severing 3D acquisition, applications, algorithms and eco-system. The ability of kernel software bundled with hardware is emphasized.

What topics we are interested in

High quality visual appearance

According to CIE Visual Appearance, this topic is based on 3D imaging technology constructed by photometric method, stereoscopy , polarized light photography, multi-view/array camera, array light and other technologies to totally solve color measurement problems. We expect to acquire PBR (Physically Based Rendering) textures by utilizing different configurations of cameras. In addition to being used for more accurate color measurement, it also includes characteristics such as refraction, roughness, transparency, surface texture, and surface normals to achieve ultra-realistic digital image data, which is further used as quality material texture of 3D models to realize visual appearance.

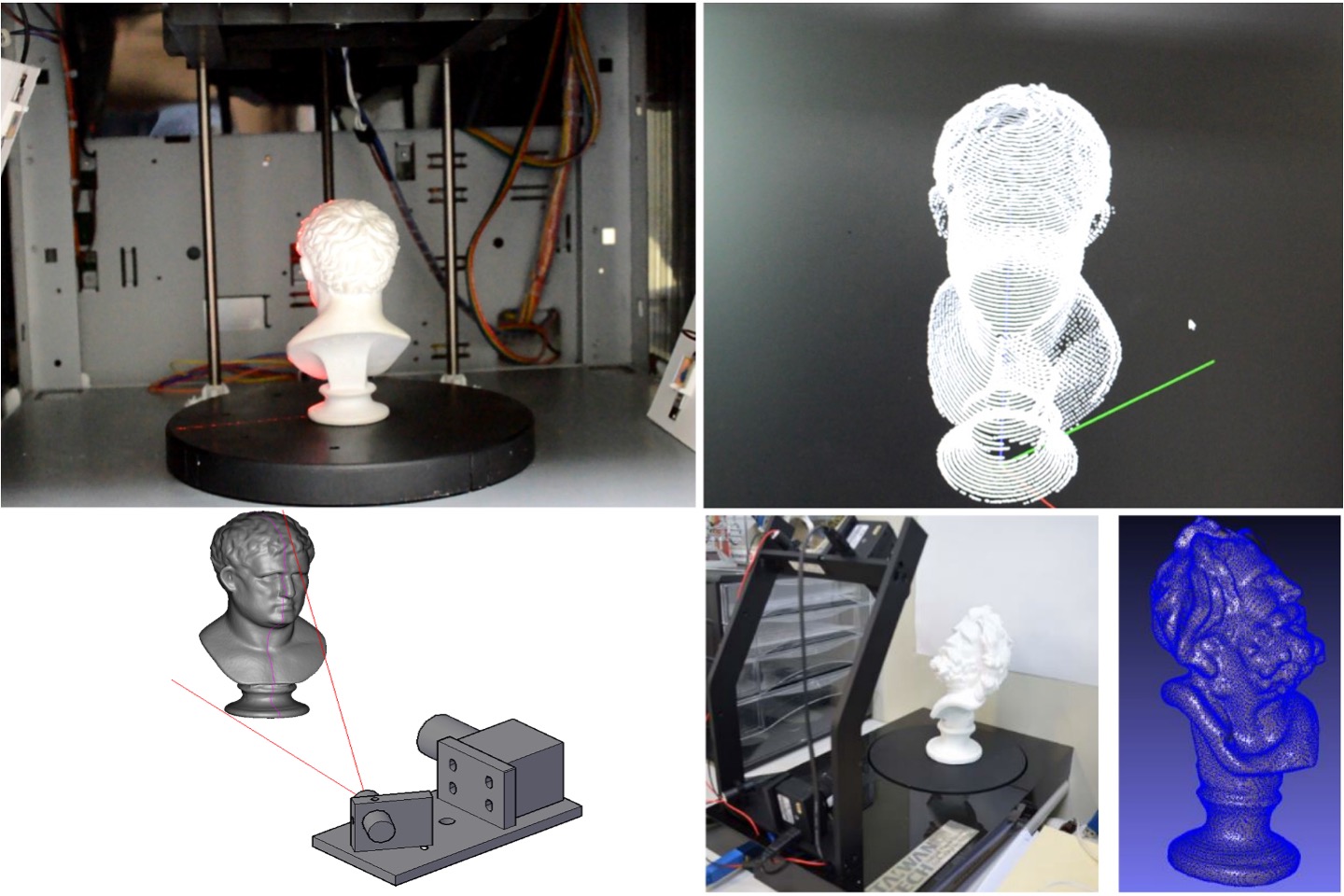

Customized 3D scanning application

Currently, 3D scanning technology is a relative mature and widely used in applications, and our team has been engaged in this field for many years. We have the expertise in the fundamental hardware mechanisms, optical principles, and algorithms associated with most mainstream 3D scanning technologies. Our strength is in developing innovative solutions not yet available in the market, with a high degree of customization to meet various specific needs, such as measurements of specific shapes, high-speed scanning, and operations in extreme conditions. We believe that ‘3D scanning’ should be as simple as the a digital camera, and thus, many of the technologies developed in our laboratory are designed with a button’ approach.

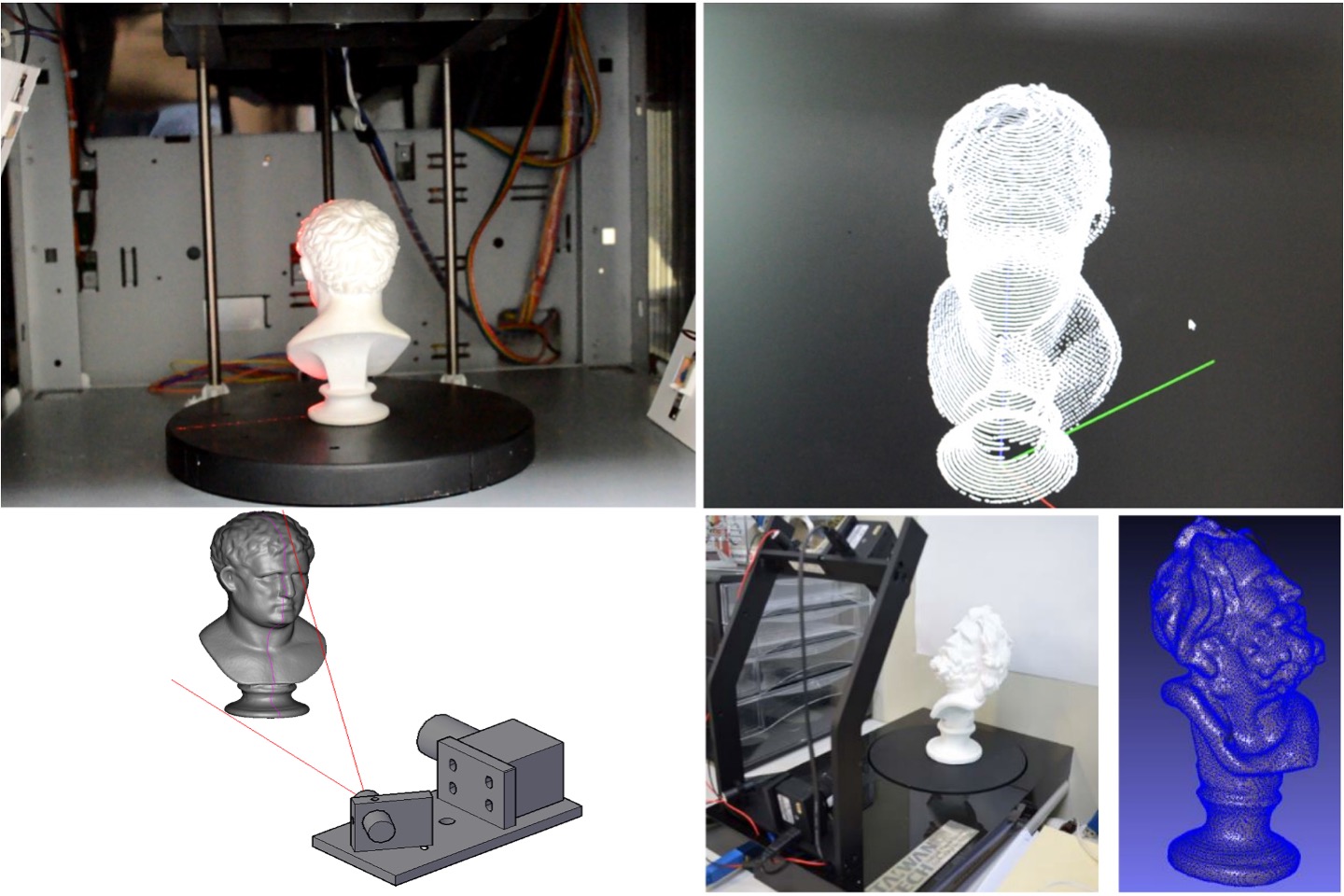

Digital dental total solutions

The digitalization is extensively utilized in the field of dentistry, covering aspects such as orthodontics, dental implants, denture manufacturing, color and shade matching, braces, treatments, professional training, etc. The use of 3D scanning and 3D printing applications has become widespread in these processes. Our team has been operating in this field for many years and has developed relevant algorithms and solutions. Digital dentistry often requires customization for specific customer needs, making the seamless integration of 3D printing and 3D scanning a highly advantageous approach.

3D printing technology

3D printing is a novel manufacturing technology that breaks away from traditional subtractive manufacturing. Its evolution is close to the introduction of 3D software and can meet the demands of high complexity and high customization in production. Our team collaborates with several domestic research teams, working towards solving the relevant software technologies required for 3D printing. This includes 3D model slicing, layer support materials, multi-material printing, color printing, processing language, and more.

Applications based on 3D computer vision

The 3D algorithms derived from computer vision can enhance the richness and precision of related applications. In past decades, we have explored areas such as AR projection, multi-perspective imaging, stereoscopic images, and computational imaging. In this field, we emphasize contemplating how to leverage 3D-related technologies to innovative applications and products. Simultaneously, we feedback to the development of new computer vision algorithm technologies.

Smart agriculture and automation

Intelligent and automation are the trends in the future development of agriculture. This field encompasses image processing, sensors, machine learning, AI and computer vision, precise color analysis, and various forms of quantification and extensive data analytics. These technologies aim to enhance the quality and efficiency of agricultural production, as well as mitigate or reduce disasters. In this domain, we incorporate technologies such as color analysis, image processing, and 3D to realize the concept of smart agriculture.

Scientific sports and competition

We are also interested in issues related to computer vision and computer graphics technologies that can enhance health, improve athletic performance, and analyze sports games. Therefore, both software development and integration of components, as well as the development of new products, are among the planned directions for our team.

3D technologies for education

Starting from graduate and university education, we are involved in the technological development of related STEAM (Science, Technology, Engineering, Arts, and Mathematics) education. This includes DIY 3D scanners, DIY 3D printers, maker education, and educational tool development. We aim to transform 3D-related knowledge into resources that can be learned at the K12 stage (kindergarten through 12th grade) and continue to promote 3D education.

Our transferred products

Laser 3D scanner(general purposes)

The patent of our team has been transformed into a commercial product, a laser 3D scanner (triangulation method). This product is characterized by its ultra low cost and self-automatic calibration. Since 2015, it has been sold by an authorized manufacturer.

Image based color inspection instrument

We utilize specific lighting conditions and industrial-grade cameras, calibrating the CIE-XYZ values of the camera through a spectrometer. The colors are then transformed to the CIE color difference standards. This process includes analysis software and allows for color measurement and color difference analysis for small, multi-colored objects with various logical approaches. The product has been manufactured and sold by the authorized manufacturer since 2020.

Structure light 3D scanner

This technology employs low-cost structured light and camera components to achieve automatic scanning. In a single scanning process, the sampling density is approximately 10 million points, with a statistical error in single-point accuracy reaching below 20 microns. The design is specifically tailored for applications focused on scanning dental models.

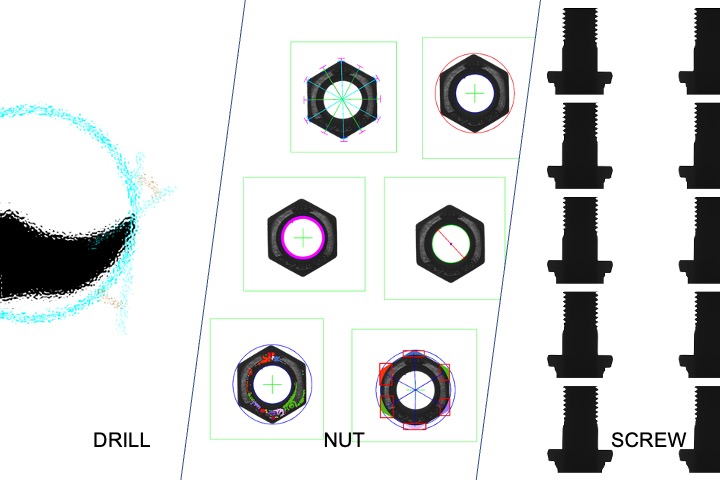

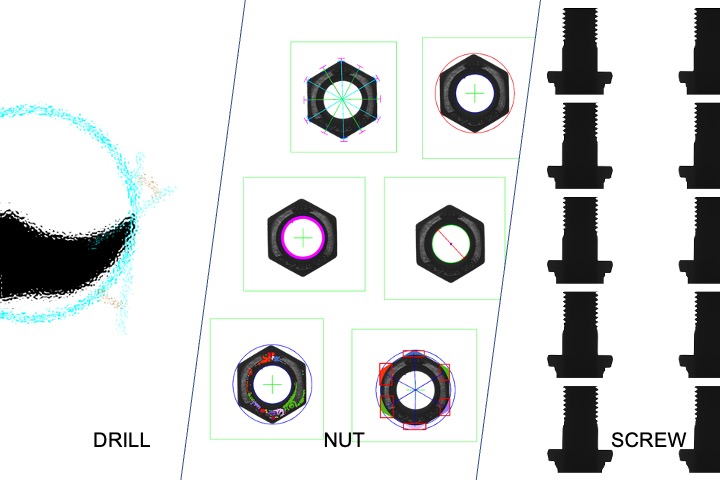

Image based automatic size inspection (AOI)

Assisting at least three manufacturers, we developed proprietary optical AOI (Automated Optical Inspection) software tailored for screws, nuts, and drill bits. This software is actively utilized in quality control, production inspection, and integrated into standalone retail software (paired with specific hardware).

Education and promotion

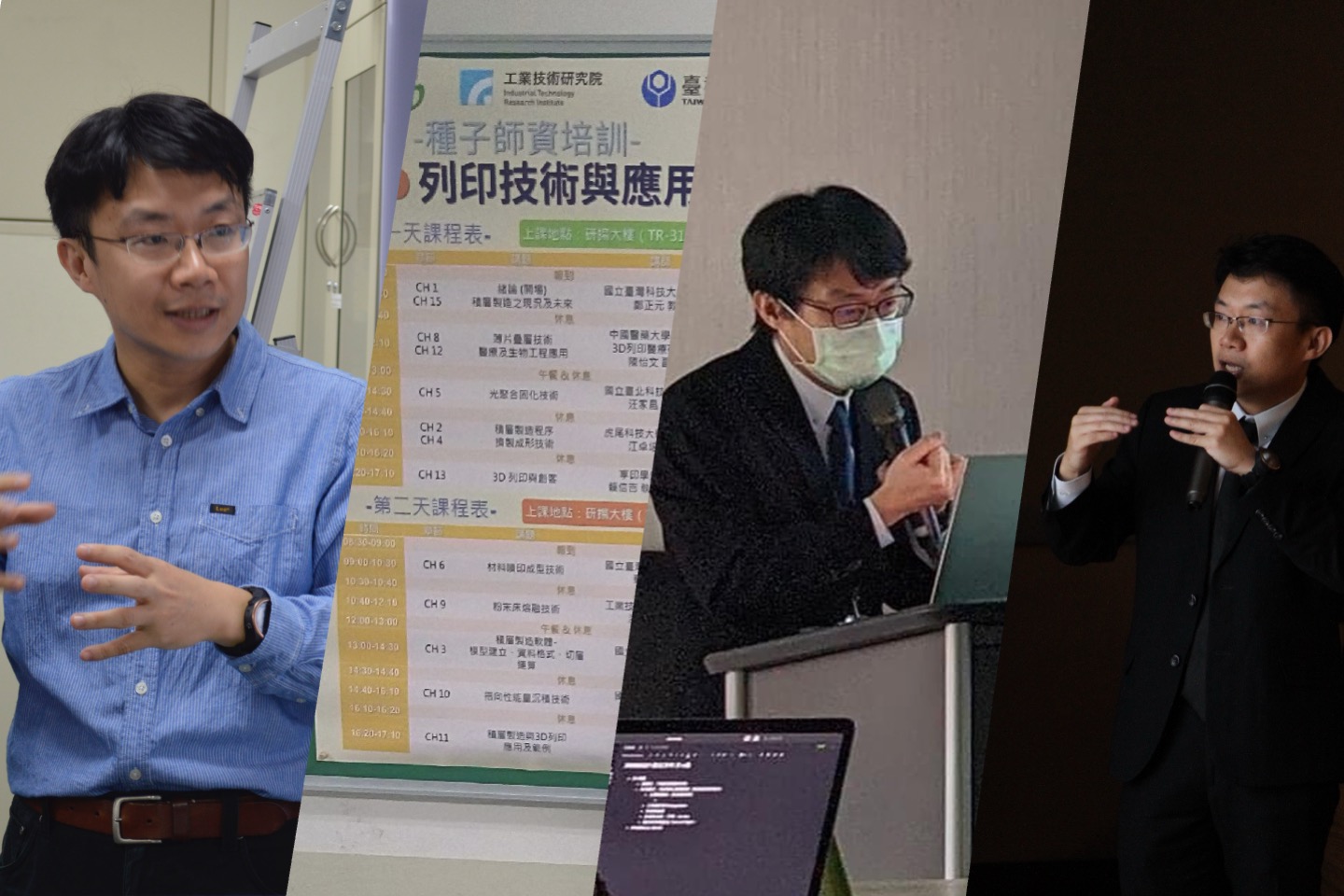

3D related education for various generations

Long-term support for educational tasks such as 3D scanning, 3D printing, and Maker, as well as the implementation of related education programs. Meanwhile, our laboratory often cooperates with schools, Ministry of Education programs, and scientific and educational units to promote 3D-related education for different generations. For example, K12 age group: Maker, STEAM education: Junior high schools and primary schools: career exploration promotion education, university 3D printing courses/3D scanning workshops, seed teacher training, credit courses and degrees, etc.

3D professional training

It has long-term cooperation with Tze-Chiang Foundation. Our lab. director is one of the main teachers of 3D technology, and provides long-term and irregular 3D technology courses for private enterprises and consultant contract, Including understanding basic 3D digital data, how to obtain 3D data, 3D expertise training, career trials, external on-the-job training courses, and serving as a lecturer for private companies.

Contact us

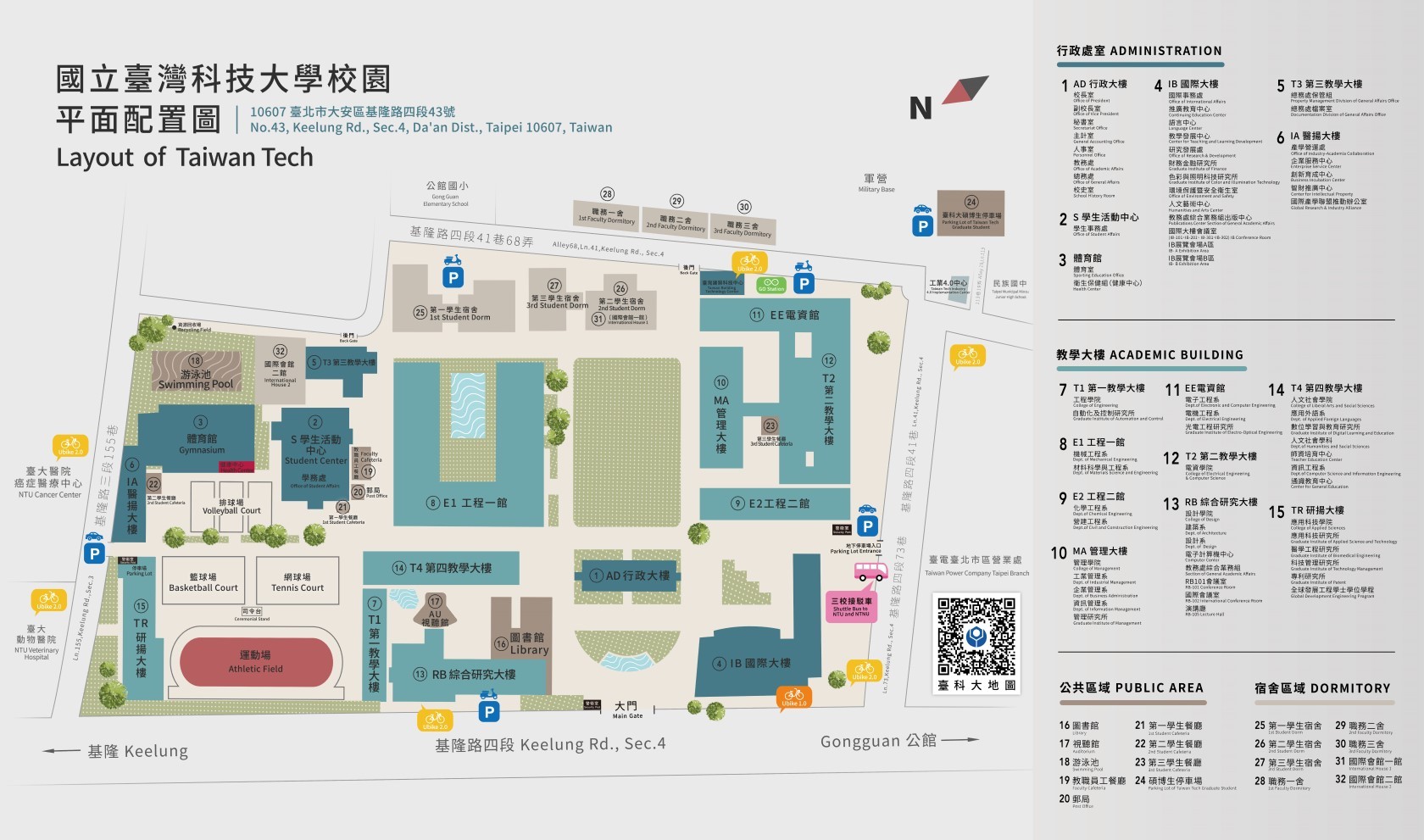

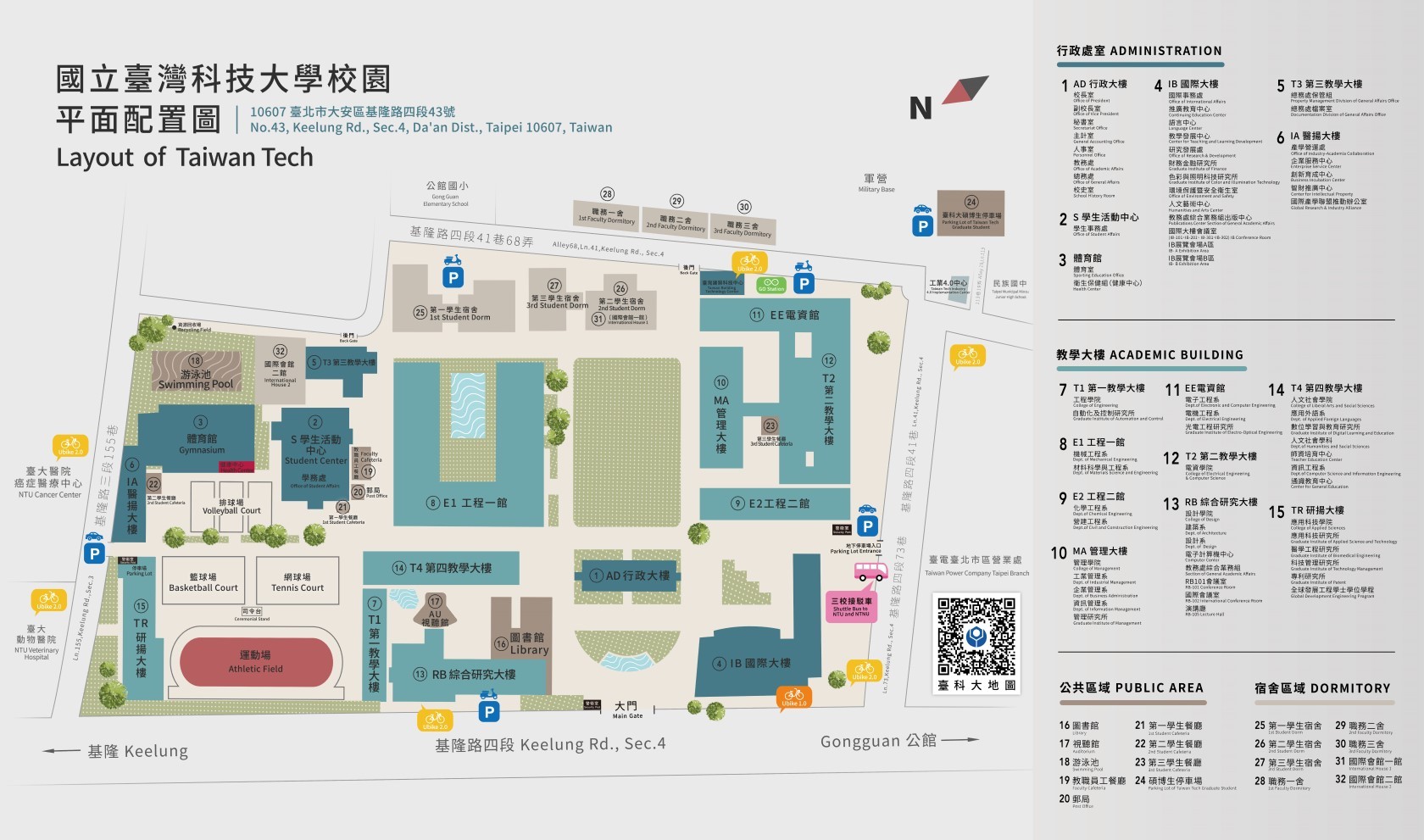

Post address

No. 43, Sec. 4, Keelung Rd., Da’an Dist., Taipei, 10607, Taiwan.

National Taiwan University of Science and Technology

Graduate Institute of Color and Illumination Technology (Intl Bld. 10F, IB1037)

Send email

Views: 20517